Resilience of the Organica Solution

The following is a short summary that is designed to address a frequent question regarding the ability of Organica-powered WWTPs to respond to the introduction of toxic materials to the wastewater influent stream.

Background

As urbanization edges towards once remote, existing, and often aging wastewater treatment plants, Organica has seen increasing opportunities to upgrade these WWTPs with the Organica solution. The benefits of doing so include either increased capacity or reduced footprint, reduction of the “no build” buffer around the WWTP, lower energy consumption, and more resiliency to toxins in the WW stream. One such upgrade project has been constructed in Eastern Europe. In this project, Organica upgraded the existing biological reactors with its solution – including plant racks and Organica’s proprietary biofiber media carrier that mimics plant root structures. In late 2011, the civil contractor had partially installed some elements of the Biomodule on one of six treatment trains at the facility; in particular Organica had installed the plant racks and the proprietary biofiber media, but it had not yet completed the placement of the actual plants. The remaining five treatment trains had not yet been upgraded; construction of those was completed in 2012.

Shock Loading Event

Experience has shown that due to the higher biological diversity, and the greater quantity of beneficial biomass in the system, Organica-powered WWTPs display higher resilience against unexpected shock loading, resulting in higher resistance to sudden changes in influent compared to conventional solutions. The robust characteristics of using an enhanced ecosystem that can maintain higher quantities of biomass within the reactors were demonstrated during the aforementioned construction project, providing a unique opportunity to compare conventional suspended activated sludge solutions to the Organica solution.

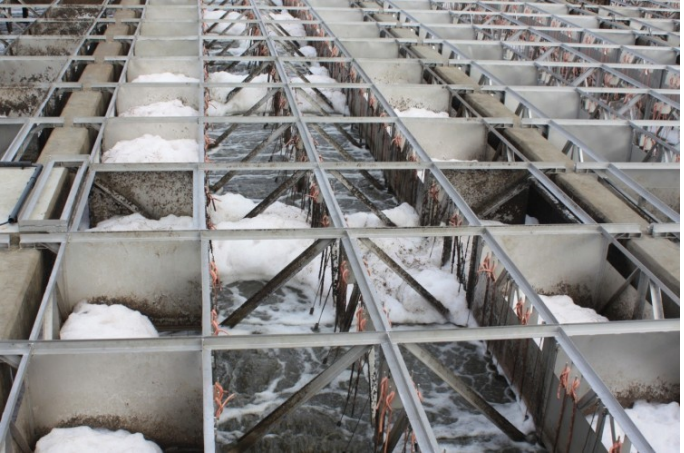

On December 14th, 2011 a “shock loading” or poisoning event occurred at the facility significantly impacting its performance. It is not known what caused the incident, however we believe that the co-located sludge digester malfunctioned and allowed pure sludge (approximately 100x the concentration of typical influent) to be recirculated into the WWTP. Although the installation of the Biomodule in the one reactor where the upgrade project had begun was not yet complete, the event still provided clear evidence of the relative stronger resiliency offered by a more diverse ecology. As seen in the photos below, the impact of the poisoning event on the reactors where the activated sludge technology was in operation was much greater than that on the reactor that had been partially converted to Organica. The shock load caused an extreme foaming condition in the OTHER reactors, forcing the operator to shut them down and correct the issue. On the other hand the quantity of foam in the reactors partially upgraded with the Organica solution was nominal, and the reactor was able to continue to operate without being shut down.

Photos of the Event on December 14, 2012

Foam overflowing from reactor with traditional activated sludge technology.

Manageable quantities of foam in reactor with Organica Biomodules installed.

The reactor in the background contains the Organica Biomodules, where the one in the foreground is operated with activated sludge.

The reactor on the right contains the Organica Biomodules, while the one on the left is using activated sludge.