Posted on October 7, 2015

Hint: land costs US$25,000 per square meter.

by Suresh Muthusamy, Sales Director – South East Asia at Organica Water

It is never easy to convince a developer to pull a wastewater treatment plant (WWTP) out of a building basement (where it is typically built to hide it from view) and into the open at ground level. This is especially true in the heart of a large capital city such as Jakarta (Indonesia), where land commands a premium and is often valued at over US$25,000 per square meter. At these price levels, it is obviously important for real estate developers to maximize floor space in their high-rise office building or condominium tower over wasting space by constructing an ugly, odorous wastewater treatment facility. For decades, this specific “out of sight, out of mind” mind-set has prevailed among most developers in Southeast Asia when it comes to wastewater management. These facilities tend to be built away from the sight of residents and visitors due to all the negativity associated with living or working close to them.

Current Situation

Before proposing they should locate their wastewater treatment facility among the open green area in the development, we had to understand why they typically choose to hide it. Of course, it is assumed they will desire to build maximum floor space, sell more commercial space and churn more dollars when land costs over US$25,000 per square meter. But as I progressed in the discussions with the developer, I found that it is not the only reason developers normally prefer to place the wastewater treatment plant in the basement of buildings. Additionally they identified the following reasons for locating wastewater facilities “out of sight”:

- Offensive odours

- Poor aesthetics

- Decreased land value around the wastewater facilities

It is an unwritten rule that in most of the high-rise developments, these wastewater treatment facilities are relegated to being built deep down in the basement with a significant increase in cost. But the underlying fact is, the design and equipment of these treatment plants are typically supplied by small contractors who fail to understand the engineering behind wastewater treatment. From my experience, these facilities start producing foul odour approximately three to five years’ after they have been commissioned, when the plant reaches its biological design load and hydraulic capacity.

How did water get its precious status?

Parts of Jakarta city are already 3 to 4 meters below sea level and continue to sink every day due to heavy extraction of groundwater, burdened by the increasing load of a vertically growing city. Since the utilities operating in Jakarta struggle to meet the water demand of the city, most commercial establishments took the most easily available shortcut of pumping water from below ground to fulfil their needs. It was not until a few years ago that Jakarta implemented various measures to address this depleting groundwater table. Initiatives such as mandatory rainwater harvesting, mandatory green areas in every development, and a maximum cap of groundwater extraction per building was introduced. Additionally, a progressive tariff for groundwater extraction was implemented, pushing the price of water as high as US$5 per cubic meter!

Such policies hit the bottom line of developers and commercial establishments and pushed them to consider reusing and recycling wastewater more seriously. It was only then that they realised the value of this most essential resource. This led to a sudden growth of membrane suppliers in the market who provided quick fix solutions to reuse and recycle by offering skid mounted ultrafiltration and reverse osmosis units.

Learning the Hard Way

Although Jakarta found initial success with membrane based systems to deal with their increasing demand for clean water, many developers did not understand that these are extremely sensitive to organic fouling. When the WWTP upstream is not operating efficiently and treating the wastewater, these membrane based solutions failed miserably. These problems led to the introduction of Membrane Bioreactor (MBR) systems, which combine a membrane process like microfiltration or ultrafiltration with a suspended-growth bioreactor. MBR systems claimed to address the footprint issues and also the need for clean water. Although this appeared to be “THE” solution that Jakarta city has been longing for, this moment was also short lived when it was discovered how energy intensive MBR systems can be, in addition to the high cost of future membrane replacements required.

Hopes Redeemed with Organica

After having gone through various solutions, it was finally understood that the actual problem lies in the biological process. When Organica approached the developer and explained the advantages of our Food Chain Reactor (FCR) solution, they commented that it was “too good to be true”: our system would provide effluent quality as good as that from a MBR system, while consuming less than half the power consumed by a MBR system! Further, the Organica FCR solution has significant advantages over a conventional wastewater treatment system, occupying only one third the footprint and producing 40% less sludge.

Being a commercial establishment in the heart of Jakarta, developers are often faced with a lot of challenges, including peak hour electricity surcharge, and sludge handling trucks having limited access to the plant (only between the hours of 10PM and 5AM).

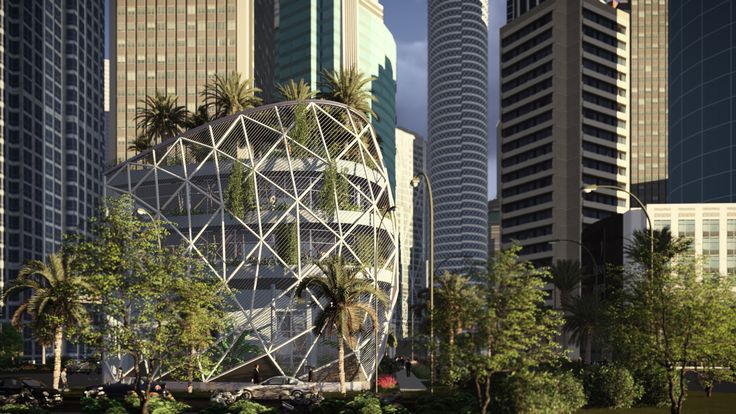

Considering all the above challenges, the Organica solution was able to fit perfectly in a well-developed city centre dotted with high rise buildings all around. To blend this wastewater treatment plant into the surroundings, our team of architects gave a completely modern look to this 2,000 m3 per day WWTP:

Water Reclamation Gardens: The Organica WWTP

At Organica, we do not design “yet another” wastewater treatment plant, as every project is unique, with its own specific demand drivers and client needs. So we cannot deal with each of them in a “cookie-cutter” approach. We have to create a specific approach that tailors our solutions to the scenario appropriately.

We design local water reclamation gardens that help our clients reclaim wastewater and typically utilize it for various non-potable applications such as gardening, cooling tower makeup water, and toilet flushing. All of these come at a very competitive capital and operating cost with the added bonus of an odour-free facility with an aesthetically pleasing botanical garden appearance.

This psychological revolution of changing the typical image of wastewater treatment facilities has already begun in Indonesia and we are finding more and more success with clients increasingly interested in our solution.

Who can refuse such a tempting treat? Change is coming your way!

Learn more about How We Do Design, What is a Good Fit for Organica FCR in Greenfield Applications, and more here!